DIY Tubular Webbing Belts

Many outdoor gear brands sell thin webbing belts. These belts aren’t meant to hold much gear. They simply hold your pants up. The thin, pliable webbing makes for a svelte belt that can be comfortably worn under a pack hip belt or a climbing harness. The webbing also tends to be of a low quality, and the belts are often priced ridiculously high. Why pay $15 for something that you can make yourself at little cost, if not for free?

I had worn a Frequent Flyer Belt from The Wilderness Tactical on a daily basis for a number of years. It is an excellent belt, but I occasionally found the wide and thick webbing, which is appropriate for some uses, to be uncomfortable and cause chafing under the heavy hip belt of my pack. As an experiment, I purchased a Patagonia Friction Belt when it was heavily discounted during a sale. That worked well for a while – it was more comfortable under my pack – but the webbing used was very low quality. It was also still a bit stiff. I thought, why should there be any stiffness at all to the belt? It serves no purpose in the backcountry.

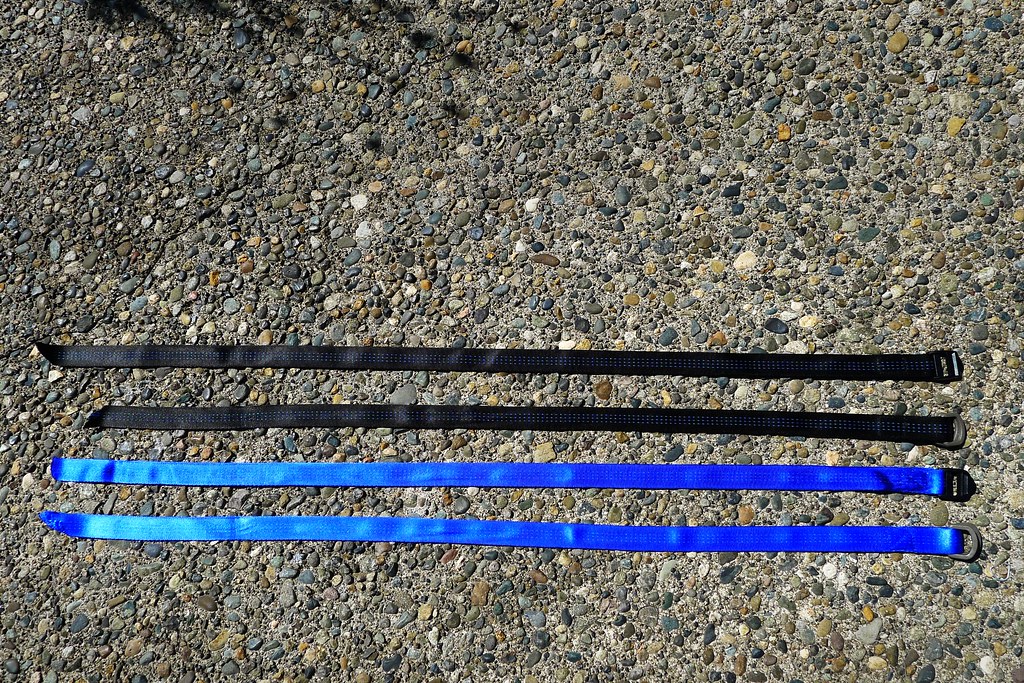

I made my first belt in early March. Initially I intended for it be used only when backpacking, but it proved functional enough that I soon made three more and wear them on a daily basis. The webbing is stiff enough to hold a multi-tool and a knife, which is the most that I carry on my belt these days, both in wilderness environments and urban.

The webbing I used is simple tubular webbing. It is strong, and yet softer and more pliable than most flat webbing, making for a comfortable belt. Any climber most likely has yards of the stuff laying around. I happen to use BlueWater 1” webbing, which exceeds the strength of military-spec webbing, but, in a belt, this is irrelevant. My stitching will certainly blow long before the webbing.

After sewing, I cut the webbing so that the total length of the belt is about 39”. That provides plenty of length to use the belt as improvised lashing, if I ever need it.

I first began using ladderlocs as the buckles. This worked, but I later experimented with using two D-rings. I now prefer the smoother operation of the D-ring buckle. I have experienced no slippage with either type of buckle. Both the ladderlocs and the D-rings I had laying around from previous projects, or from old gear (I always salvage the hardware from old, ratty gear before throwing the rest away).

The total cost to me for all of these belts was zero. If you had to buy the webbing and hardware, you may be looking at around $2. A far cry cheaper than any similar belt you’d find in a store! The total weight of a single belt is 50 grams (1.76 oz).